January 2026

Quantum Cascade Lasers (QCLs) are unipolar lasers based on intersubband transition in semiconductor superlattice structures. They are a highly effective means of achieving lasers with operation wavelengths in the mid-infrared spectrum (2-20 microns) and provide industry standards in these areas. Applications for lasers in this wavelength include gas sensing, healthcare monitoring, molecular spectroscopy, infrared imaging and atmospheric physics.

Challenge

QCLs have undergone a rapid development in the last 30 years since their invention in 1994 by Jérôme Faist et al. at Bell Laboratories [1]. The National Epitaxy Facility has been developing QCLs’ epitaxial growth, fabrication, and characterization since early 2000s, when the first QCL was developed by Metal Organic Vapour Phase Epitaxy (MOVPE) [2]. Challenges remain in scaling up this technology by using multi-wafers MOVPE industrially compatible reactors with vertical growth. The precise control of the epitaxy at the atomic level throughout the high number of layers in the superlattice QCL core is of utmost importance to ensure excellent performance of the laser. Although to date there is a variety of studies on QCLs by MBE and MOVPE, challenges remain in scaling-up such technology for full reproducibility of material quality and top performance on industrial reactors.

Solution

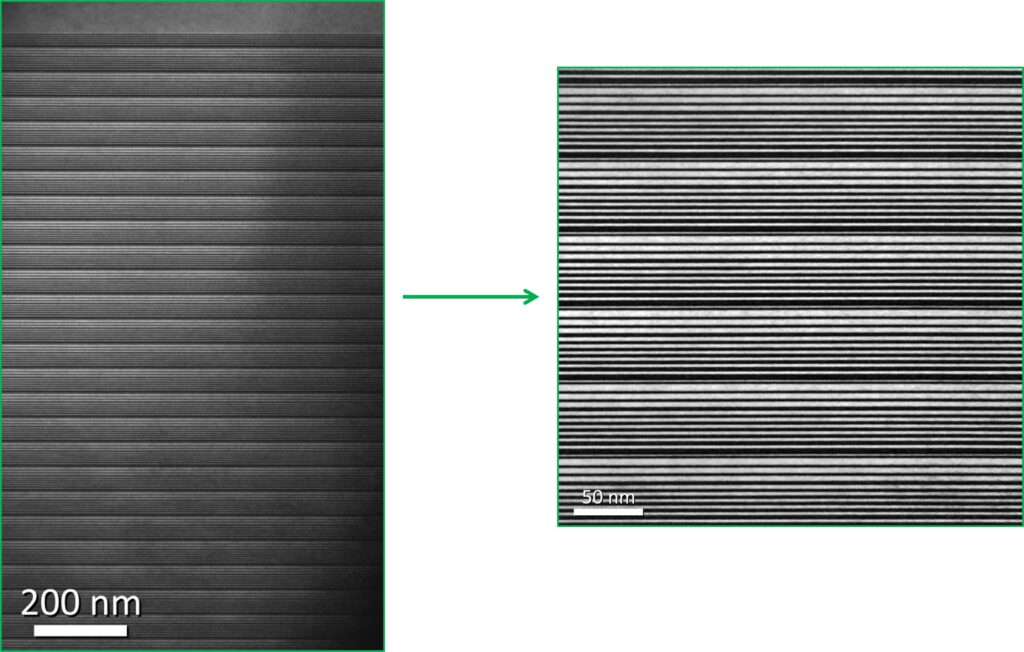

Recent epitaxial developments have led to the demonstration at NEF of the growth of full QCL devices on the industrially compatible 3×2’’ close-coupled showerhead (CCS) Aixtron MOVPE ‘JR’ reactor of the NEF, allowing for a technology transfer into industry and on studies on their reproducibility. Such QCLs exhibit high material quality, confirmed by Transmission Electron Microscopy (TEM) investigations, see Fig.1, and reproducible results in terms of laser performances (current best threshold current down to 1.55 kA/cm2 at room temperature in pulsed mode).

Tuning of the wavelength emission has been also demonstrated by precise tweaking of the layer thicknesses in the active core. Studies are currently underway to demonstrate the QCL growth and operation on sacrificial layers for transfer-printing experiments.

Figure 1 Transmission Electron Microscopy (TEM) of a QCL active region grown on the JR CCS Aixtron reactor

Key factors allowing the National Epitaxy Facility to have a leading position in this technology are:

- Both MOVPE and MBE available for QCL growth with QCLs now established on the industrially compatible showerhead JR CCS Aixtron reactor

- Establishing growth procedures for key growth parameters ensuring reproducibility and continuous improvement of laser performance

- The availability of in-house excellent electrical, optical and fabrication facilities enabling a quick turnaround and immediate feedback to growth

- Currently establishing the MOVPE growth technology on sacrificial layer for transfer printing studies

Conclusion

The National Epitaxy Facility has been developing expertise and capability in QCLs both via MBE and MOVPE, with the recent addition of QCLs on an industrially compatible reactor, available to researchers and industrial customers in the UK. The National Epitaxy Facility continues to work with academic partners and external collaborators developing the technology further for both fundamental studies and applications. New directions include improved performance, extending wavelengths, and growth of QCLs on sacrificial layers for transfer printing studies, and developing new applications.

References

[1] J. Faist, F. Capasso, D. L. Sivco, C. Sirtori, A. L. Hutchinson, A. Y. Cho, Science 264, 553-556 (1994)

[2] R. P. Green, A. Krysa, J. S. Roberts, D. G. Revin, L. R. Wilson, E. A. Zibik, W. H. Ng, J. W. Cockburn, Appl. Phys. Lett. 83, 1921–1922 (2003)