Molecular Beam Epitaxy (MBE)

University of Sheffield

There are three MBE growth systems each of which is operated in a state-of-the-art cleanroom facility based in the Nanosciences & Technology complex at the University of Sheffield – two VG V90 machines and a new dual chamber MBE cluster tool reactor complete with comprehensive in-situ atomic hydrogen cleaning and secondary ion mass spectrometry (SIMS) characterisation capability.

Combined, these three systems allow us to deliver the full range of III-V semiconductor material systems including arsenides, phosphides, antimonides, dilute nitrides and dilute bismide epitaxial structures on 2, 3 and 4” substrates.

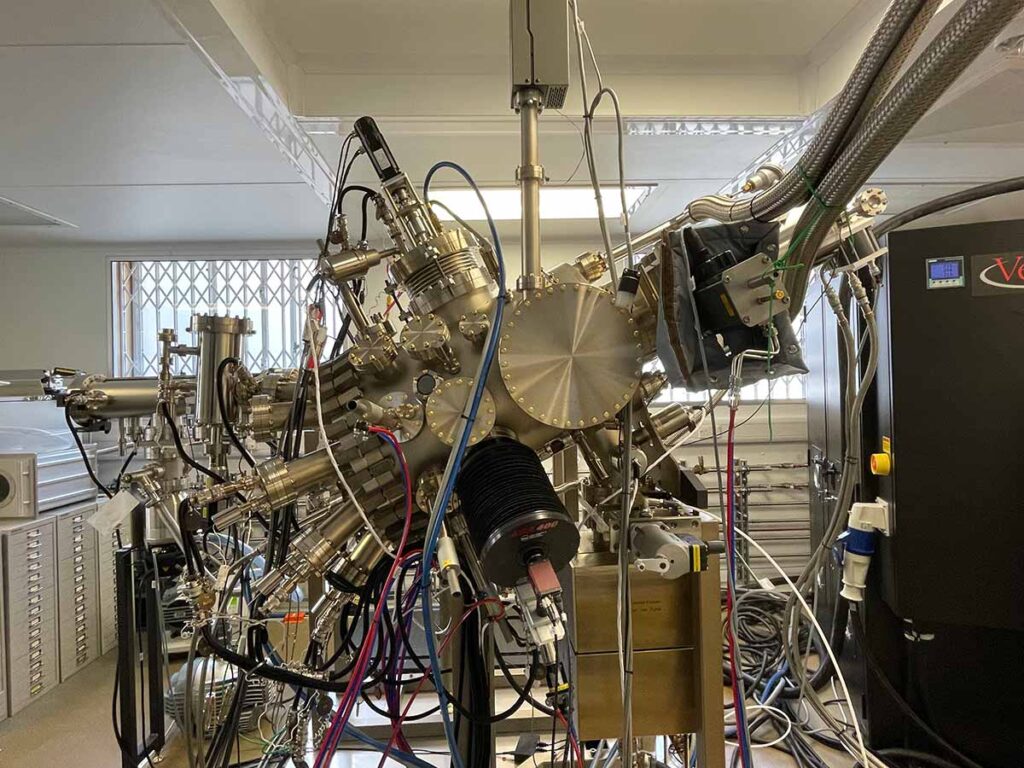

VG Semicon V90-1

- In operation since 2002

- As/P/Bi (or dilute N)

- 12 ports (2x Ga, 2x Al, 2x In, Si, Be, C)

- Wafer size up to 4″/3″/3 x 2″

Application areas:

- Lasers/VCSELs

- Microcavities

- Telecoms-wavelength quantum dots

- QCLs

VG Semicon V90-2

- In operation since 2011 (built in 2003)

- As/Sb/Bi

- 10 ports (1x Ga, 1x Al, 2x In, Si, Be, GaTe)

- Wafer size up to 4″ / 3 x 2″

Application areas:

- Mid-IR sources and detectors

- ICLs, QCLs

- APDs

- Type-II Superlattices

- InSb 2DEGs

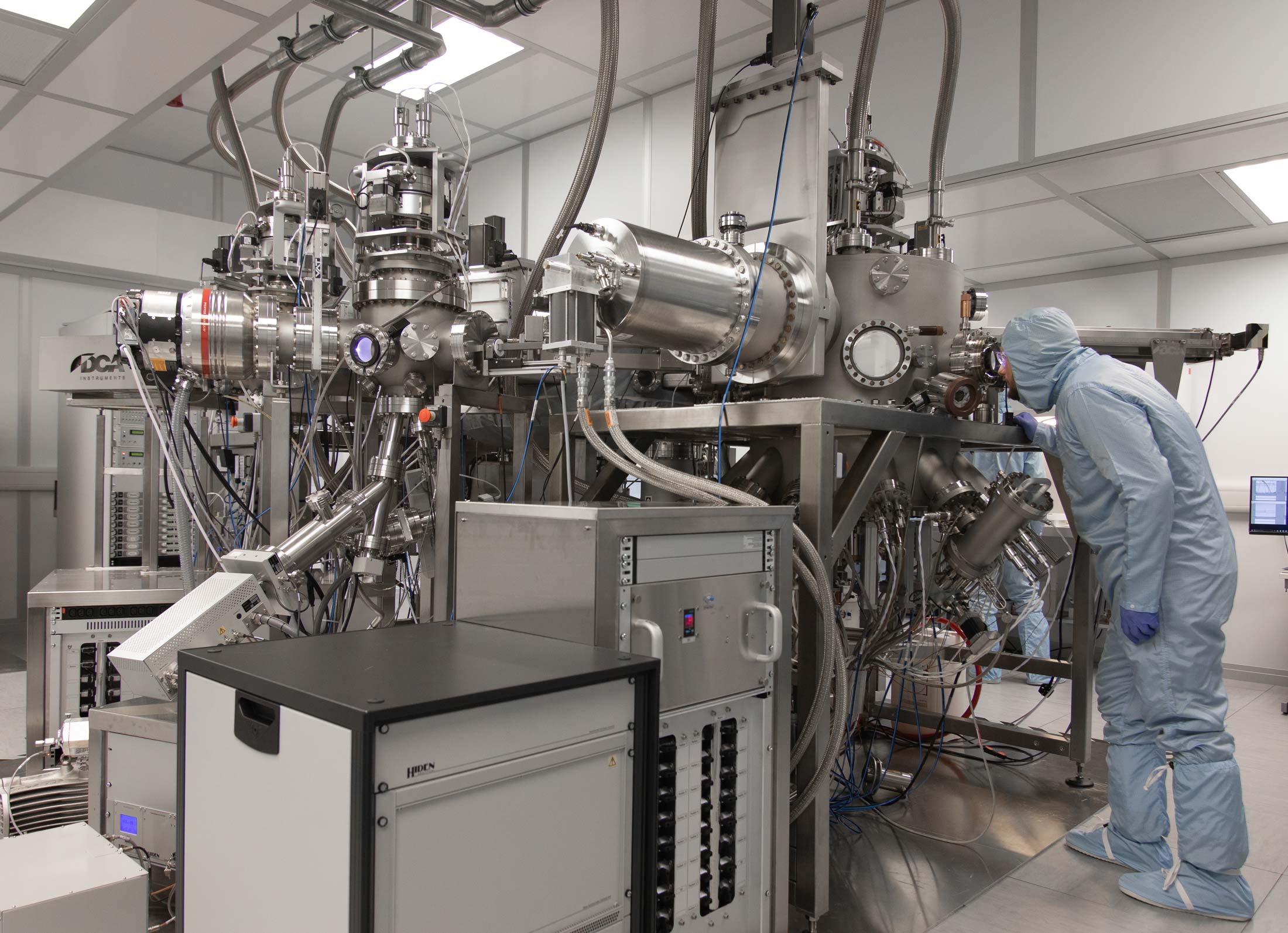

DCA Cluster Tool

- In operation since 2017

- Arsenides only

- Automated sample transfer

- Hydrogen cleaning and SIMS

- Wafer size up to 3″

Application areas:

- Quantum well and quantum dot microcavities

- Waveguide-integrated quantum dot single photon sources

- Site-controlled quantum dots

University College London

The Facility at UCL expanded from the provision of III-V materials and devices to include group IV epitaxy and hybrid III-V/Group IV epitaxy enabling capabilities in, for example, silicon photonics. They have developed growth techniques to enable a wide range of devices using III-V semi-conductors on silicon, such as InAs Quantum Dot lasers, infrared photodetectors and nanowires all grown directly on silicon substrates.

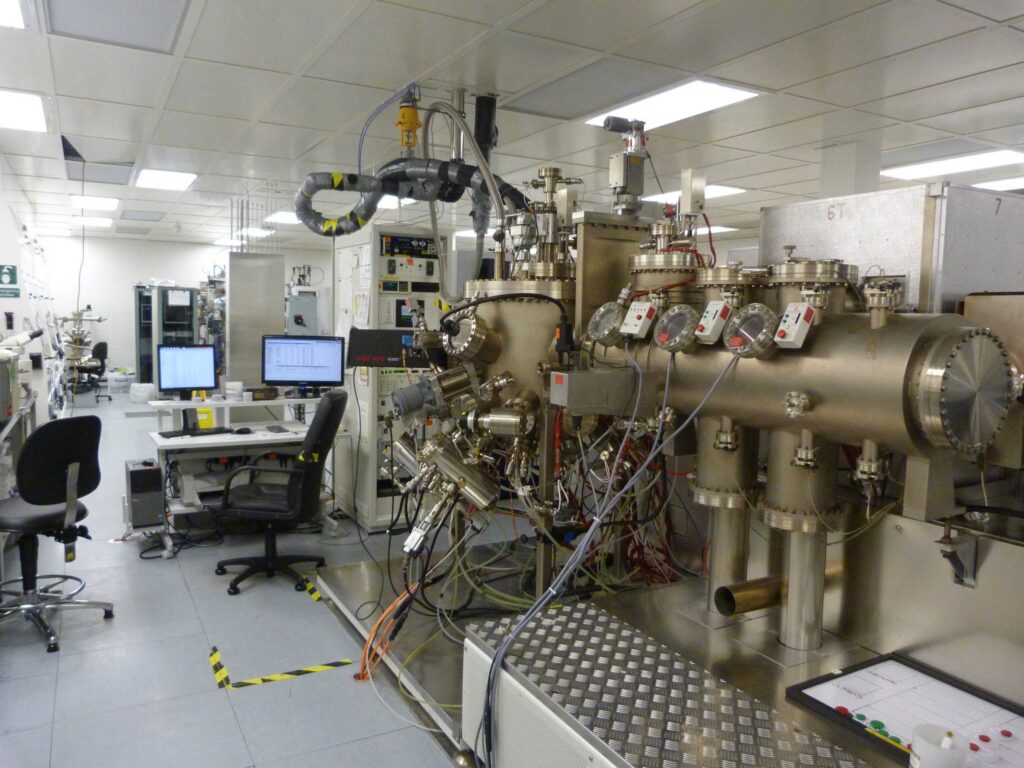

NEF at UCL has two Veeco GEN-930 MBE reactors, one of which has two chambers connected via UHV transfer system for growth of III-Vs on Si/Ge. The Facility can supply large area Silicon and Silicon/Germanium wafers up to 6″ by arrangement.

Veeco GEN 930 Twin Chamber System

The twin chamber system enables growth in group IV (Si, Ge) and group III-V (GaAs, InP) materials, without exposing the wafer to the laboratory environment.

- The ability to maintain and transfer wafers under high vacuum from one chamber to the other, ensures the growth surfaces are kept in an ultra-pristine state. Leading to a very low number defects propagating through the growth structure, which in turn results in high quality, high performance devices.

Veeco GEN 930 III-V MBE System

High quality III-V materials growth on Si for a range of projects has been developed on this machine, including:

- III-V quantum dots lasers

- self-catalysed nanowires on Si

- high performance InP based uni-travelling carrier photodiodes and

- GaAs based HEMTs.